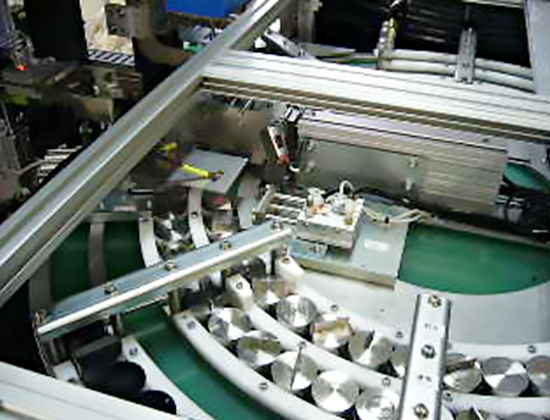

Fully Automatic Mounting Press GI-Do

back to the list

GI-Do is transported to the pressing section, and a series of steps from supply of mounting resin, pressurization, molding by heating, and engraving of specimen identification on the molded resin are automatically performed.

- Main Specifications

- Machine Specifications

Main Specifications

- The table of the loader / unloader section rotates and each specimens is transported by the cylinder.

- The resin supply hand moves onto the pressurized ram and supplies the mounting resin.

- Pressurized ram can be used for compression molding and heating of resin

- After the positioning is completed, it is transported to the printing section and engraved with the set characters.

Machine Specifications

| Applied Pressure | Max:35Mpa |

|---|---|

| Heating Temperature | 100 to 200℃ |

| Cooling | water method |

| Setting Recipe | Up to 20 can be created and saved |

| Engraved Specifications | Half-number 8 characters x 1 column |

| Power/Supply voltage | 3-phase 200 to 220V, 50/60Hz |