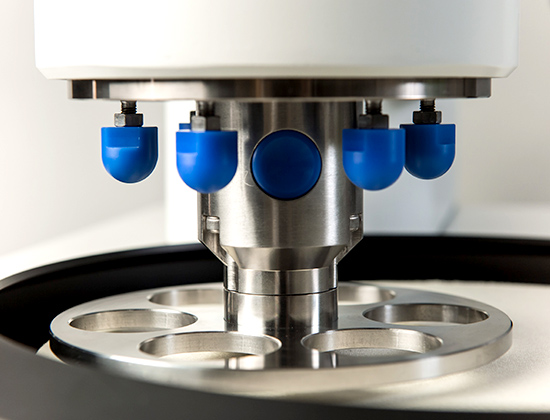

Individual Load System Automatic Polishing Machine Rana-3

back to the list

The Rana-3 is designed with an individual load method, and 1 to 6 samples can be set freely.

Since the holder rotation speed can be changed, the holder and the disc can be polished at the same rotation speed, and the polished surface does not tilt or become pencil-shaped.

he holder and the disc can rotate forward and backward.

- Main Specifications

- Machine Specifications

- movie

Main Specifications

-

Polish without losing parallelism!

With the recommended polishing method, the holder and disc should rotate at the same speed and in the same direction in order to perform grinding with no loss po parallelism in the workpieces.

Rana-3 allow the rotation speed of the holder to be changed, which makes it possible to grind workpieces in the same direction and at the same rotation speed with no loss of parallelism.

In addition, the disc and holder rotation can be reversed, allowing for easy hand polishing even for left-handed users.

- Grinding: SiC paper or polishing pad

- Disc rotation speed: 200rpm/Holder: 200rpm

- Fine polishing: DIA +polishing cloth

- Disc rotation speed: 65 to 150rpm/ Holder: 65 to 150rpm

-

Automatically increase/reduce pressure for the set number of seconds

Both Rana-3 and 30 machines can automatically increase or reduce the pressure applied to a specimen.

This function can be configured to increase pressure gradually for the set number of seconds from start.

The settings can also be configured to increase or decrease pressure gradually at the set number of seconds. -

Change polishing conditions(pressure, rotation speed) in two steps!

Two different movements can be programmed to a single polishing process to enable variations.

for example. With fragile material and material with sharp edges, operation can start at low pressure and low speed, gradually increasing to a higher pressure and higher speed. -

Memory for up to 16polishing conditions!

Up to 16 polishing conditions can be programmed.

When preparing more than one specimen, polishing conditions can be set for each specimen, allowing fore efficient operation.

| Power Supply |

Single-phase 100V, 50/60Hz or single-phase 200 to 220V 3-phase 200 to 220V, 50/60Hz single-phase 220V |

|---|---|

| Dimensions/Weight | W450×D460(to the back) ×H500mm(690mm when the head is lifted)/ 65Kg |

Polishing Area

| Disc Size |

Grinding disc: φ250mm Polishing disc: φ250mm Magnetic disc: 250mm discs sold separately |

|---|---|

| Disc Rotation Speed | 50 to 400rpm(forward/reverse switchable) |

| Motor Output | 400W (100/200V: geared motor) |

| Operation |

Waterproof touch panel, emergency stop button incl. Digital automatic stop per timer storage of up to 16 polishing conditions ABC setting(3 configurable polishing condition steps) |

| Supply/drain water function | Opening/closing of water supply cock.(attached water supply/drain hose) |

Specimen Rotation Area

| Holder Rotation | 50 to 200rpm(forward/reverse switchable) |

|---|---|

| Motor Output | AC120W brushless motor |

| Number of Specimen | Selectable from 1 to 6 (max. 3 with φ50mm) |

| Specimen Holder |

25, 30, 40, 50mm; inch diameter, custom sizes(Optional) Production of other custom sizes is possible. (holder sold separately) |

| Applied Pressure | 10 to 50N per s@ecimen |

| Lubricator | Standard accessory(Analog flow-rate adjustment type) |

| Primary Air Source |

Required(0.5 to 0.7MPa) Separate regulator also required for sources above 0.7MPa) |